Hydraulic Services

Practical Support for Hydraulic Systems

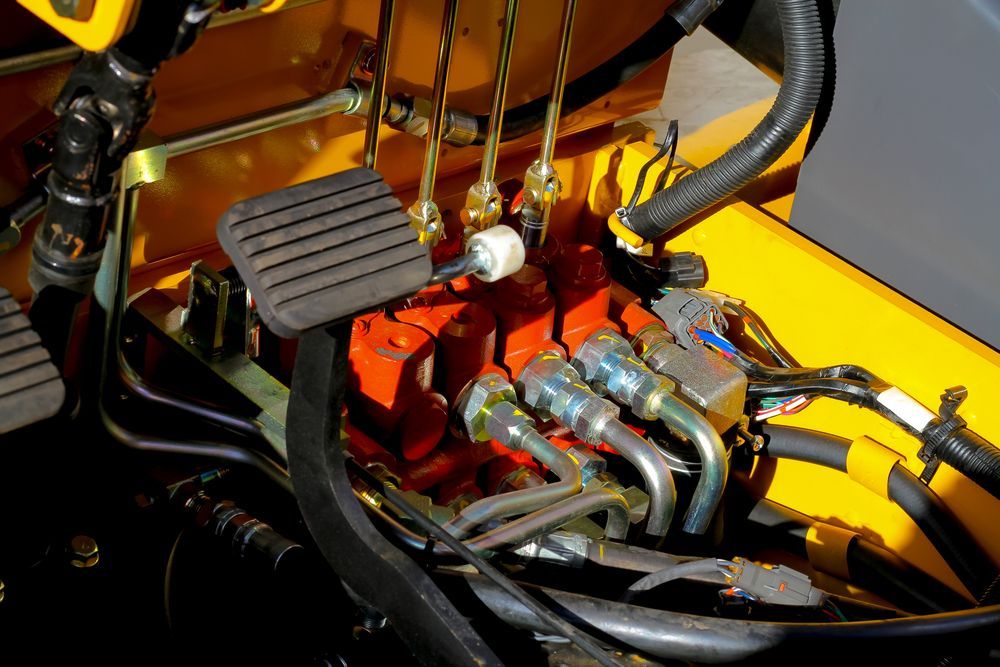

Hydrofit Service provides comprehensive hydraulic services to clients across Wollongong, delivering mobile support for equipment used in transport, construction, industrial operations, and agriculture. Based locally with over 20 years of experience, Hydrofit Service works directly with businesses and machinery operators to maintain, repair, and inspect hydraulic systems with precision and efficiency.

Services include system diagnostics, cylinder repair, hose replacement, and preventative maintenance—delivered on-site to reduce downtime and disruption. The team operates fully equipped mobile units and follows structured service procedures to ensure consistency and mechanical safety.

Technicians are experienced with a wide range of hydraulic applications, including mobile plant, heavy vehicles, and fixed industrial systems. Support is tailored to suit field conditions, industry compliance, and the client’s immediate needs. Equipment is assessed thoroughly before repair, with clear communication throughout the service.

For hydraulic services in Wollongong, contact Hydrofit Service on

0449 014 101.

Hydraulic Repairs

Mobile hydraulic repairs for trucks, machinery, and equipment. We troubleshoot pressure issues, replace faulty components, and restore system integrity directly on-site to reduce downtime and disruption.

Hydraulic Cylinder Repair

We disassemble, inspect, and rebuild hydraulic cylinders. Services include seal replacement, rod repairs, and performance testing to restore function and maintain safe, efficient system operation.

Hydraulic System Diagnostics

Accurate on-site hydraulic system diagnostics using pressure testing, flow analysis, and temperature checks. We identify hidden faults in valves, pumps, and hoses to support timely, targeted hydraulic maintenance.

What does a hydraulic service include?

A standard hydraulic service typically includes visual inspection, fluid level and quality checks, hose and seal inspections, and performance testing for pressure and flow. The service may also involve tightening fittings, replacing worn components, checking for internal leaks, and cleaning filters or strainers. The goal is to ensure the hydraulic system operates safely and efficiently under load.

How often should hydraulic equipment be serviced?

The frequency of hydraulic servicing depends on the type of equipment, operating conditions, and manufacturer recommendations. Heavy-use machinery may require servicing every 250–500 hours of operation, while lighter-duty systems might be inspected every 1,000 hours. Regular servicing helps detect wear and contamination early, reducing the risk of system failure or reduced efficiency.

What are common signs that a hydraulic system needs servicing?

Signs include slower response times, loss of pressure, visible leaks, unusual noises, overheating, and inconsistent movement. Other indicators include fluid discolouration, jerky operation, or difficulty holding load. These issues can be caused by fluid contamination, worn components, seal failure, or internal damage and should be addressed promptly through inspection and repair.