Hydraulic System Diagnostics in Wollongong

- Over 20 years of hydraulic expertise

- Fast, mobile repairs that minimise downtime

- Reliable service backed by state-of-the-art tools

Request a Call Back

Thank you for contacting Hydrofit Service.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Wollongong Hydraulic System Diagnostics

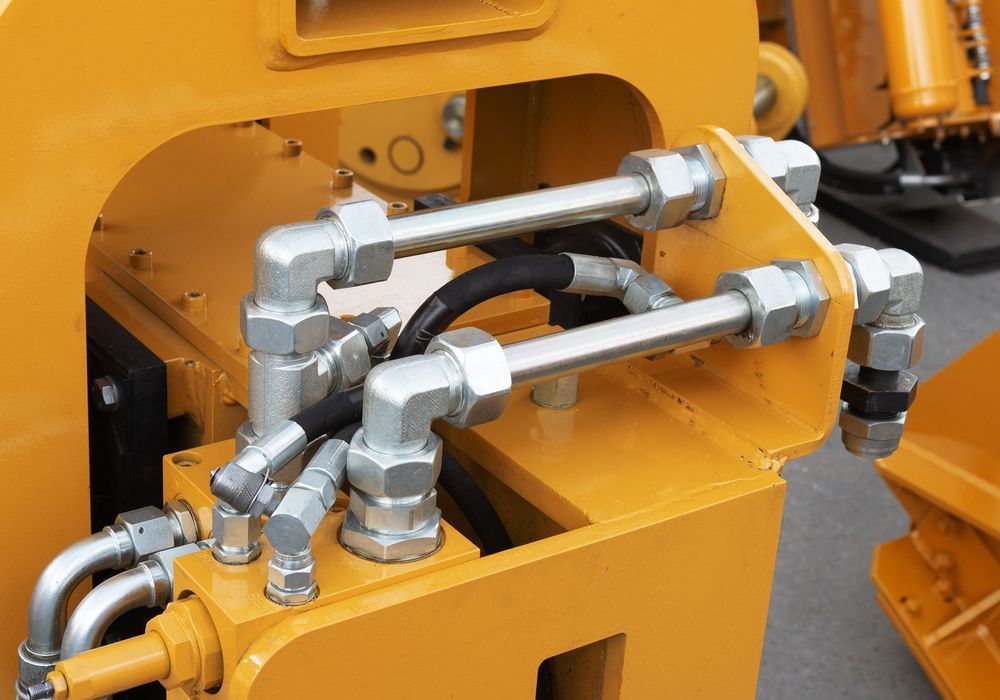

Hydrofit Service offers precise, mobile hydraulic system diagnostics for machinery and equipment throughout Wollongong and nearby areas. We use pressure testing, flow evaluation, and system inspection to identify faults before they escalate.

Whether it’s an unexpected pressure drop, sluggish response, or unexplained fluid loss, we bring advanced diagnostic tools directly to your site for fast, on-the-spot assessment. With over 20 years of field experience, we understand how system design, application load, and environment can affect function.

Our team provides site-based evaluations that support reliable hydraulic repairs and preventative maintenance plans.

- Pressure and flow testing on-site

- Suitable for mobile and fixed systems

- Fast fault identification

We work with machinery operators, fleet managers, and site supervisors to troubleshoot underperforming hydraulics without the need to transport equipment.

Call

0449 014 101 to book a hydraulic diagnostic inspection in Wollongong.

What Our Diagnostics Include

Our service begins with a full assessment of system behaviour—checking operating pressures, load performance, fluid quality, and leak points. We use pressure gauges, flow meters, and infrared temperature tools to track abnormal performance and pinpoint possible failures.

The aim is to isolate problems in pumps, valves, actuators, or control sequences.

We diagnose agricultural, construction, transport, and industrial machinery across a variety of makes and system layouts. Whether the issue is a restriction, cavitation, internal leak, or timing fault, we report clearly and recommend a tailored path forward.

Where immediate repair is possible, we carry the tools and parts to get started on-site.

- Pump efficiency testing

- Valve, cylinder and line assessment

- Thermal and flow profiling

Our approach is built around clarity—avoiding guesswork and providing you with concrete data to guide maintenance and repairs.

Why is hydraulic diagnostics important?

Hydraulic diagnostics are essential for identifying the root cause of poor system performance, pressure loss, or mechanical failure. Rather than replacing components blindly, diagnostics allow for targeted repairs, improving system reliability and reducing unnecessary part changes. It’s especially important for complex or high-use systems where downtime affects operations or safety.

What are common signs of hydraulic issues?

Signs include slow or erratic movement, reduced lifting capacity, unusual noises, high operating temperatures, or visible leaks. These can indicate issues like fluid contamination, worn seals, internal leakage, or pump failure. Diagnostics are used to isolate the exact cause by measuring pressure, flow, and temperature at various points in the system.

What equipment is used in hydraulic diagnostics?

Technicians typically use calibrated pressure gauges, flow meters, temperature sensors, and sometimes digital sensors or infrared thermometers. These tools help identify where the system is under- or over-performing. Combined with physical inspections and fluid analysis, this equipment provides a complete performance profile for any hydraulic setup.

Can hydraulic diagnostics be done on-site?

Yes, most diagnostics are performed on-site using mobile testing equipment. This allows technicians to evaluate systems under real working conditions and apply pressure or flow tests to confirm problems in real-time. On-site diagnostics also speed up the repair process, as faults can be addressed immediately if parts are available.